Let's work through an example for the 6.7:1 gearing with a 5x3 prop. This combination has a motor RPM about midway between the max efficiency and max power RPM's. Its 0.34 amp draw is well within the 0.50 amp max discharge capability of the ET-90 LiPoly cell. The predicted motor measures columns show a predicted amp draw of 0.36 amps, which is very close to the actual 0.34 measured amp draw. Predicted efficiency is 47%, which is 90% of the 52% max efficiency for this motor. Predicted power is 0.61 Watts, which is 96% of the max power of 0.64 Watts for this motor. Overall, this is a very good combination for this motor. In fact it is probably the best combination if prop diameter is not a constraint. The higher pitch 5x4.3 prop has a higher amp draw with the 6.7:1 gear ratio but develops less thrust. Although the motor RPM is closer to the max power RPM, it is below that RPM. So, it would seem to be moderately over propped. Overall we find that just about the best combination for this motor is either the 6.5:1 or 6.7:1 gearing and a 5x3 prop.

If you are building a semi-scale plane with a 10 to 12 inch or so wing span and would like the prop to not hit the ground, the 5-inch prop is probably not an option. A prop the size of the U80 or maybe a slightly larger 3.5-inch prop is probably a better choice. From the table we can see that the U80 is a good match with 4:1 gearing. It develops about 9g thrust with high percentages of max efficiency and max power. If a bit more thrust is needed the larger diameter and higher pitch 3.5x2.7 prop delivers 11g thrust, but efficiency drops.

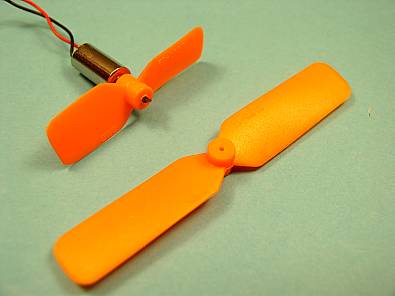

One way to save weight on the lightest models might be to eliminate the gearbox, which typically weigh about 0.7g, and run the motor direct drive. To explore this possibility I tested the motor DD with a GWS 2.5x0.8 prop. Then, I trimmed the prop to a smaller diameter, tested it, trimmed it again, tested, and so on. The results are shown near the top of Table 2 along with the prop diameter in millimeters after trimming. The first thing worth noting is that the untrimmed prop is clearly overloading the motor, and also pulls more amps than the ET-90 cell can provide. The motor RPM is far below the max power RPM. Only the 37mm trimmed prop has an RPM close to the max power RPM. The picture below shows the untrimmed and the 37mm trimmed prop, which can best be described as a "nub." The best prop is probably the 41mm version. The amp draw is on the high side for this motor, and I don't know how long it will last at a 0.43 amp draw. It ran only slightly warm so motor life might be ok. The other thing to note is these were very crudely trimmed props where the ends were simply chopped off and then sanded thin. It may be possible to get better thrust by trimming this prop to have a slightly larger diameter than 41mm, but with thin tapered blades. If this is attempted the goal should be to get a much nicer trimmed prop that pulls about 0.43 amps, and hopefully with higher thrust.

|

| For direct drive static tests a GWS 2.5x0.8 prop was cut down in stages and tested at each diameter. Shown here is the original prop next to one cut down to 37mm (0.94 inches). |