According to materials by J. Kalina and K. J. Hammerschmidt.

(I realize that the overview is not complete because a complete overview goes beyond the limits of this www site.)

The compressed carbon dioxide motors were accompanying the very beginnings of the aircraft heavier than air. The first flying motor

models were driven by compressed air and compressed carbon dioxide motors.

CO2 motors meant another development level after the compressed air motors. A great future was forecast to these motors during the

First World War, although at the beginning they were heavier than compressed air motors. Unlike them, they were working for a longer time, but in a

cold weather they were easy to get frozen.

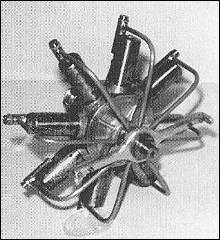

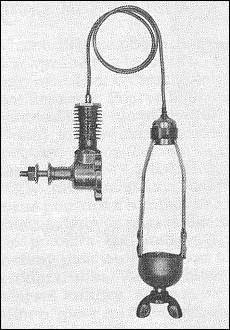

The best known motors were again those made by Max. Braune - a successful manufacturer of compressed air motors. Max. Braune introduced

production of start-type three-, five- and eight-cylinder motors. The motors were running also on compressed hydrogen, however best on carbon dioxide.

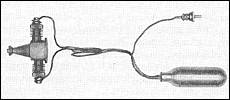

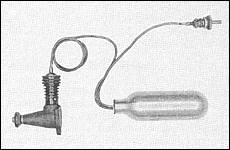

They were equipped with a pressure controller for controlling the gas flow and speed. The filling device connected to the carbon dioxide cylinder was

fitted with a pressure relief valve limiting the pressure in the model tank to 5000 kP. It was possible to borrow the cylinders from any beer tapping

facility. Not even with a carbon dioxide motor was, however, the model able to take off with due to the fast pressure drop in the tank. After opening

the gas inlet to the motor and initiating the propeller rotation with a cord actuator it was necessary to launch such a model from the hand. |

A

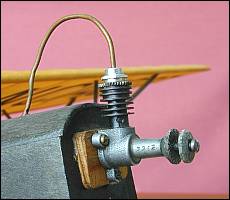

miniature flat twin cylinder motor (MJ-140V) was designed in 1973 with the use of certain parts from the previous motors. The motor featuring a weight

of 10.9 grams (without a propeller), which can be attached to the model with two bolts, is an ideal driving unit for small flying dummies.

A

miniature flat twin cylinder motor (MJ-140V) was designed in 1973 with the use of certain parts from the previous motors. The motor featuring a weight

of 10.9 grams (without a propeller), which can be attached to the model with two bolts, is an ideal driving unit for small flying dummies.