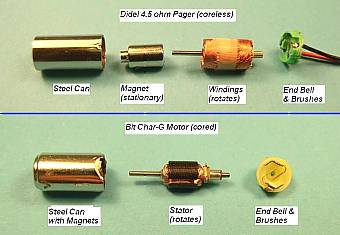

Most of the 6mm motors available are coreless. The top panel in the picture below shows the Didel 4.5 ohm pager motor after it has been taken apart. There is a steel can that has the stationary magnet permanently attached to the inside of the front bell. Normally this magnet does not come out but was drilled out and removed for this illustration. A set of coreless windings fits over this magnet and has a back plate where the windings attach to the commutator. A shaft passes through the commutator, through the stationary magnet, and out the front bell. Essentially the windings are a drum that rotates around the stationary magnet.

The bottom panel in the picture below shows a Bit Char-G motor after it has been taken apart. The steel can has curved ferrite magnets inside it. The stator is simply a very small version of a traditional cored stator. In fact, this one measures just 4.2mm in diameter. And, finally there is a plastic end bell with the brushes. The Mabuchi 6mm motor that Toytronics sells looks very similar inside to the Bit Char-G motor.

|

| In a coreless pager motor the windings rotate around a stationary magnet. In a traditional cored motor the cored stator rotates inside a set of magnets. |

The motors in these tests include most of the 6mm Didel motors, several of the Bit Char-G motors, several of the Bit Clone motors, and a few of what I am calling surplus pager motors. I do not have all the Bit Char-G or Bit Clone motors so present results for those I do have. The Snow Globe Bit Clone motors were provided by Billy Stiltner. The ZipZap Bit Clone motors I purchased at Radio Shack in a hop-up kit. The Bit Char-G motors I obtained nearly two years ago, early on in the Bit Car craze, from a hobby shop in Hong Kong in genuine Bit Char-G packaging. I don't know if Bit Char-G cars still come with these cored type motors. The Didel pagers I obtained directly from Didel. But, most of them are also available from various other vendors who carry Didel products. I've also included the 7mm Didel pager for comparison as people have often been curious how this larger pager motor performs.

Focus of Tests & Methodology

In this set of tests I simplified the problem of evaluating different motors by using just one gear ratio and prop. I chose a 5-inch prop as much larger and the prop would either look funny or would hit the ground for typical scale or stick planes sized about right for pager motors. I chose the 6.7:1 gearing as the higher ratio from the Didel 81t spur gear is more difficult to fit inside a scale cowl, unless the plane had a radial engine, and would also require a larger prop. I've also focused on single stage gearing. Thus, this set of tests is really an exercise in finding the best motor for a given prop and gearing. It is possible that for a different prop and gearing a different motor might do better. However, if one motor outperforms another motor by a sufficient margin, then it is likely to also do so for other props and gear ratios.